Why is stainless steel resistant to rust and corrosion?

Stainless steel has become one of the most widely used metals in construction, manufacturing, and household applications because of its unique ability to resist rust and corrosion. From kitchen sinks to skyscrapers, stainless steel’s durability and attractive appearance make it a preferred material in industries worldwide. But what makes this metal so special? Why does it outperform ordinary steel in harsh environments? In this article, we will explore the science behind stainless steel’s resistance to rust, its advantages, and why it is a material of choice in places like Stainless Steel Singapore, where both performance and aesthetics matter.

The Science Behind Stainless Steel’s Resistance

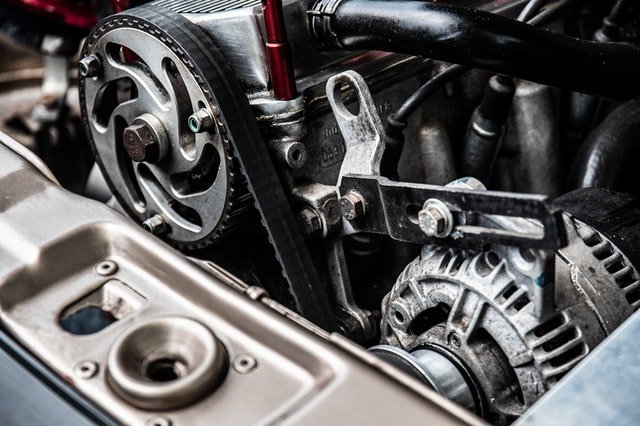

Ordinary steel is primarily made of iron, and iron has a natural tendency to react with oxygen and moisture in the environment. When this reaction occurs, iron oxide, commonly known as rust, forms on the surface. Rust weakens the structure and causes the steel to deteriorate over time.

Stainless steel, however, behaves differently. The secret lies in the addition of chromium, an essential element that gives stainless steel its rust-resistant properties. Typically, stainless steel contains at least 10.5% chromium by mass. When exposed to oxygen, chromium reacts to form a very thin, invisible layer of chromium oxide on the steel’s surface.

This protective layer acts as a barrier that prevents oxygen and moisture from penetrating the underlying metal. Unlike rust, which flakes off and exposes more metal, the chromium oxide film stays intact and even repairs itself if scratched or damaged. This self-healing property is the primary reason stainless steel remains durable in harsh environments.

Additional Alloying Elements

Besides chromium, stainless steel often includes other alloying elements that enhance its resistance to corrosion:

- Nickel improves toughness and stability in acidic conditions.

- Molybdenum boosts resistance against chlorides and saline environments, making it ideal for marine applications.

- Carbon adds strength when used in controlled amounts.

Together, these elements create a versatile material that resists rust far better than ordinary steel.

Types of Stainless Steel and Their Resistance

Stainless steel is not a single type of metal but a family of alloys. The most common types include:

- Austenitic Stainless Steel – Contains high levels of chromium and nickel, offering excellent corrosion resistance and weldability. This type is commonly used in kitchen equipment, chemical plants, and architectural projects in places like Stainless Steel Singapore.

- Ferritic Stainless Steel – Magnetic in nature and moderately resistant to corrosion. It is often used in automotive applications and household appliances.

- Martensitic Stainless Steel – Strong and hard but less corrosion-resistant than austenitic steel. It is widely used in knives, tools, and surgical instruments.

- Duplex Stainless Steel – A combination of austenitic and ferritic properties, offering high strength and superior resistance in aggressive environments such as offshore platforms.

Everyday Benefits of Stainless Steel

Because of its unique ability to resist rust and corrosion, stainless steel offers multiple benefits:

- Durability – It can withstand years of use without significant wear.

- Hygiene – Its smooth surface is easy to clean, making it ideal for food processing, hospitals, and kitchens.

- Aesthetic Appeal – Stainless steel maintains its shine and modern look even after decades.

- Low Maintenance – It requires little upkeep compared to other metals that corrode easily.

- Sustainability – Stainless steel is 100% recyclable, which aligns with green building practices.

These advantages explain why stainless steel is so popular in industries ranging from construction to household appliances.

Why Stainless Steel Matters in Singapore

Singapore is a global hub for construction, marine engineering, and advanced manufacturing. With its humid tropical climate and constant exposure to moisture, choosing the right material for buildings, infrastructure, and machinery is crucial. Ordinary steel would quickly rust in such an environment, leading to costly repairs and replacements.

That is why Stainless Steel Singapore suppliers play a vital role in meeting the country’s industrial needs. From high-rise buildings to MRT stations and offshore oil rigs, stainless steel ensures safety, longevity, and aesthetic value. The material’s ability to resist rust in Singapore’s challenging climate makes it indispensable.

Interestingly, the same industries that rely on stainless steel often turn to lightweight alternatives for specific applications. For instance, an Aluminium Supplier Singapore provides materials that complement stainless steel in projects where weight reduction is important, such as aerospace, transportation, and architectural designs. Stainless steel offers strength and durability, while aluminium provides flexibility and lightness. Together, they shape modern infrastructure and manufacturing in the region.

Comparing Stainless Steel and Aluminium

While both stainless steel and aluminium are corrosion-resistant, their properties differ:

- Stainless Steel is stronger, heavier, and more resistant to impact. It is ideal for structural applications where durability is critical.

- Aluminium is lighter, easier to machine, and excellent for reducing overall weight in projects such as vehicles and aircraft.

For construction and heavy-duty applications in Singapore, stainless steel remains the top choice. However, industries often rely on both, which explains the importance of having trusted suppliers like Stainless Steel Singapore distributors and Aluminium Supplier Singapore businesses serving diverse market needs.

Final Thoughts

Stainless steel’s resistance to rust and corrosion lies in its unique chemical composition, especially the presence of chromium, which forms a self-healing protective oxide layer. This property makes it one of the most durable and versatile materials in the world. In regions like Singapore, where humidity and harsh conditions accelerate corrosion, stainless steel proves to be a vital material for construction, infrastructure, and manufacturing.

Whether you are sourcing from a Stainless Steel Singapore supplier for long-lasting strength or working with an Aluminium Supplier Singapore for lightweight solutions, the choice of materials can significantly impact performance and sustainability. Stainless steel, with its proven resistance, remains a symbol of durability, hygiene, and modern engineering.