What is stainless steel and how is it made?

Stainless steel is one of the most versatile and durable materials used in industries across the world. From kitchen utensils to skyscrapers, this remarkable alloy plays a key role in modern manufacturing and construction. Its resistance to corrosion, sleek appearance, and strength make it a popular choice for builders, engineers, and manufacturers. In regions like Stainless Steel Singapore, the demand for high-quality steel products continues to grow due to the city’s thriving construction and industrial sectors. To understand why stainless steel is so important, it’s worth exploring what it is, how it’s made, and why it is often compared with materials like aluminium sheet Singapore for various applications.

What Exactly Is Stainless Steel?

Stainless steel is an alloy primarily made of iron, with a minimum of 10.5% chromium content. This chromium forms a thin, invisible layer of oxide on the steel’s surface, known as the passive layer. This layer prevents oxygen and moisture from reaching the underlying metal, which makes stainless steel resistant to rust and corrosion.

In addition to chromium, other elements such as nickel, molybdenum, silicon, and manganese may be added to enhance its properties. For example, nickel improves the metal’s strength and ductility, while molybdenum boosts corrosion resistance, especially against chlorides found in saltwater.

The result is a metal that not only looks elegant with its mirror-like shine but also performs exceptionally well under harsh conditions. This is why Stainless Steel Singapore suppliers provide various grades suited for everything from kitchenware to marine construction.

The Raw Materials Behind Stainless Steel

The production of stainless steel starts with gathering the right raw materials. These include:

- Iron ore: The primary ingredient that forms the base of the alloy.

- Chromium: Essential for corrosion resistance.

- Nickel: Adds strength, ductility, and resistance to high temperatures.

- Carbon and manganese: Used in small amounts to adjust hardness and strength.

- Other alloys: Such as silicon and molybdenum, depending on the desired grade.

Each ingredient must be carefully measured and combined to ensure the final product meets strict quality standards, especially in industrial hubs like Stainless Steel Singapore, where precision and performance are critical.

How Is Stainless Steel Made?

The process of making stainless steel involves several key stages that transform raw minerals into a durable, gleaming metal.

1. Melting and Mixing

The raw materials are melted together in an electric arc furnace at extremely high temperatures — often exceeding 1500°C. This process can take several hours. The molten metal is thoroughly mixed to ensure uniform composition throughout.

2. Removal of Impurities

Once the mixture reaches the desired chemical composition, impurities such as carbon and sulfur are removed. This step is crucial because excess carbon can make the steel brittle. In modern steelmaking facilities, advanced refining techniques like argon oxygen decarburization (AOD) are used to achieve the perfect balance.

3. Casting

The purified molten stainless steel is then cast into various shapes, such as slabs, billets, or blooms, depending on the intended use. Slabs are typically rolled into sheets or plates, while billets can be made into rods or wires.

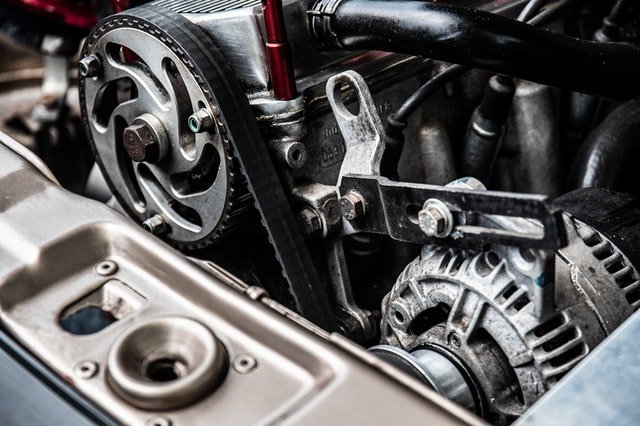

4. Hot Rolling and Cold Rolling

The cast forms are then hot rolled to achieve the desired thickness. Hot rolling occurs at high temperatures and helps reduce the size of the slabs while improving their grain structure.

Afterward, cold rolling is performed at room temperature to refine the finish, improve strength, and ensure dimensional accuracy. This process is often used for producing thin stainless steel sheets that require a smooth, shiny surface.

- Heat Treatment and Annealing

Next, the material undergoes annealing, a heat treatment process that removes internal stresses and improves flexibility. Annealing also helps restore corrosion resistance by reforming the passive oxide layer.

6. Descaling and Finishing

During hot rolling and annealing, scale (a rough oxide layer) forms on the steel’s surface. This is removed using acid baths in a process called pickling. Afterward, the steel is polished, brushed, or coated to give it the desired appearance — from mirror finishes to matte textures.

7. Cutting and Shaping

Finally, stainless steel sheets or bars are cut to size using laser cutting, shearing, or plasma cutting techniques. This is the stage where Stainless Steel Singapore manufacturers deliver customized shapes for clients across construction, automotive, and manufacturing industries.

Types of Stainless Steel

There are several types of stainless steel, each designed for specific applications:

- Austenitic: Contains high chromium and nickel; excellent corrosion resistance and non-magnetic. Common in kitchenware and chemical equipment.

- Ferritic: Magnetic and cheaper, with moderate corrosion resistance; used in automotive parts.

- Martensitic: High strength and hardness; used for knives and tools.

- Duplex: Combines properties of austenitic and ferritic steels; ideal for marine environments.

The variety allows industries in Singapore to select the most suitable grade for each project, ensuring efficiency and longevity.

Stainless Steel vs Aluminium Sheet

While stainless steel is known for its durability and corrosion resistance, aluminium sheet Singapore also enjoys wide usage due to its lightweight and excellent conductivity. Aluminium is softer and easier to shape, making it suitable for roofing, cladding, and packaging. However, stainless steel provides superior strength, heat resistance, and a premium aesthetic appeal.

In applications requiring both strength and appearance — such as architecture, food processing, and transportation — stainless steel often becomes the preferred choice. On the other hand, aluminium’s lightweight nature makes it ideal for projects where reducing weight is crucial, such as in aerospace and automotive industries.

Conclusion

Stainless steel is a remarkable material that combines beauty, strength, and longevity. From its intricate manufacturing process to its wide range of applications, it continues to play a vital role in shaping modern infrastructure and technology. In markets like Stainless Steel Singapore, where quality and innovation drive demand, the alloy remains a cornerstone of progress. While materials like aluminium sheet Singapore serve complementary roles, stainless steel’s resilience and versatility ensure it remains an essential part of our built environment — from industrial machinery to elegant architectural designs.