What are the different grades of stainless steel and their uses?

When it comes to construction, manufacturing, or even kitchen appliances, stainless steel plays a vital role due to its durability, resistance to corrosion, and aesthetic appeal. But not all stainless steel is the same. There are multiple grades, each designed for specific applications. Understanding these grades can help engineers, architects, and consumers make the right choices. In Singapore, businesses often source high-quality stainless steel Singapore products for projects that require long-lasting and reliable materials, from kitchen fittings to structural supports like a steel beam.

1. Austenitic Stainless Steel

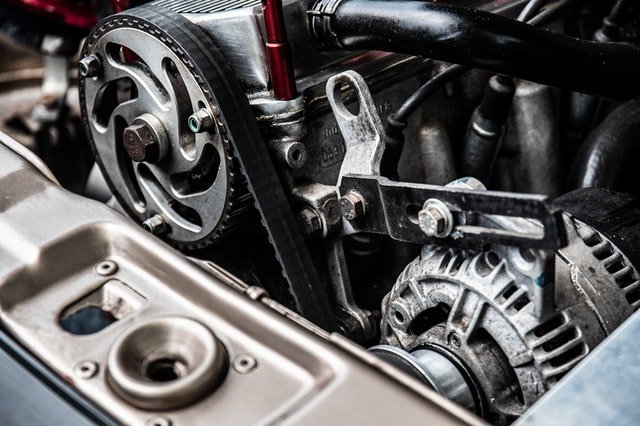

Austenitic stainless steel is one of the most widely used types of stainless steel. It contains high levels of chromium and nickel, which makes it exceptionally resistant to corrosion and oxidation. The most common grades in this category include 304 and 316.

- Grade 304: Often called 18/8 stainless steel due to its composition (18% chromium and 8% nickel), it is highly versatile. People use 304 stainless steel in kitchen equipment, food processing machinery, and architectural applications. In Singapore, 304-grade stainless steel is frequently used for countertops, handrails, and decorative panels.

- Grade 316: This grade includes molybdenum, which significantly enhances its resistance to saltwater corrosion. Marine environments, chemical processing equipment, and pharmaceutical machinery often rely on 316 stainless steel. When structural projects involve outdoor environments or coastal locations, engineers prefer steel beam designs made with 316-grade material.

Austenitic stainless steel is non-magnetic and easily fabricated, which is why it dominates industries where precision and appearance are critical.

2. Ferritic Stainless Steel

Ferritic stainless steel contains higher levels of chromium but little to no nickel. It offers moderate corrosion resistance and is magnetic, which can be beneficial in certain industrial applications. Common grades include 430 and 446.

- Grade 430: This is widely used in kitchen appliances such as dishwashers, ovens, and automotive trim parts. It is cost-effective and resists oxidation in moderate environments. In Singapore, manufacturers often select grade 430 for affordable home appliances without compromising durability.

- Grade 446: Known for excellent resistance to high-temperature oxidation, 446 stainless steel is ideal for furnace components, boilers, and heat exchangers. Engineers may even design steel beam supports for industrial plants using this grade due to its ability to withstand extreme heat.

Ferritic stainless steel offers a balance between cost and corrosion resistance, making it suitable for decorative and structural applications where extreme corrosion resistance isn’t required.

3. Martensitic Stainless Steel

Martensitic stainless steel contains higher carbon content, making it strong and hard. It is also magnetic but less resistant to corrosion than austenitic and ferritic types. Common grades include 410 and 420.

- Grade 410: This grade is hardenable through heat treatment and is commonly used in cutlery, knives, and surgical instruments. It provides strength and moderate corrosion resistance, which is why it’s often preferred in tools that must retain sharp edges.

- Grade 420: With higher carbon content than 410, 420 stainless steel offers excellent hardness and edge retention. Manufacturers often use it for surgical scalpels, scissors, and other high-strength tools. In industrial settings, smaller structural components or supports may utilize 420-grade stainless steel where wear resistance is essential.

Martensitic stainless steel is ideal for applications that demand strength and durability over corrosion resistance.

4. Duplex Stainless Steel

Duplex stainless steel combines properties of austenitic and ferritic types, providing high strength and excellent corrosion resistance. Common grades include 2205 and 2507.

- Grade 2205: This is a balanced duplex stainless steel, suitable for chemical tanks, piping systems, and offshore oil platforms. In Singapore, the material is highly sought after for industrial projects requiring steel beam frameworks that resist stress corrosion cracking.

- Grade 2507: With even higher corrosion resistance, this super duplex grade is ideal for highly corrosive environments, such as seawater handling and marine construction. Structural engineers favor this grade when longevity and reliability are top priorities.

Duplex stainless steel offers an ideal combination of toughness and resistance to pitting, which is a common issue in chloride-rich environments.

5. Precipitation-Hardening Stainless Steel

Precipitation-hardening stainless steel is designed to achieve high strength and hardness through heat treatment. Common grades include 17-4 PH and 15-5 PH.

- Grade 17-4 PH: This grade is used in aerospace components, chemical processing, and even precision instruments. It balances high strength and corrosion resistance.

- Grade 15-5 PH: Similar to 17-4 PH, it is used for aerospace and defense applications, particularly in structural components that require precise tolerances.

Precipitation-hardening stainless steel allows engineers to design steel beam structures with exceptional strength-to-weight ratios, which can reduce overall material costs while maintaining performance.

Conclusion

Choosing the right stainless steel grade depends on the specific requirements of the project. From the kitchen to offshore construction, each grade offers unique benefits. In Singapore, businesses sourcing stainless steel Singapore products must consider corrosion resistance, strength, magnetism, and temperature tolerance when selecting materials. Structural components such as a steel beam can vary significantly in performance based on the stainless steel grade used. By understanding these differences, manufacturers, architects, and engineers can ensure safety, durability, and cost efficiency in their projects.