Offshore Uses of Duplex 2205 Bolts in Corrosive Environments

Offshore platforms experience one of the most difficult working conditions globally. Metal is assaulted on a day-to-day basis by saltwater spray, severe winds, high pressure, and fluctuating temperatures. Bolts and fasteners might seem insignificant, but they prevent significant systems. Failure can be severe and expensive in case they fail. That is why there is a great number of offshore engineers who use Duplex 2205 Bolts in the critical joints. We should see how these bolts perform in expensive circumstances, and in what place they find their greatest application at sea.

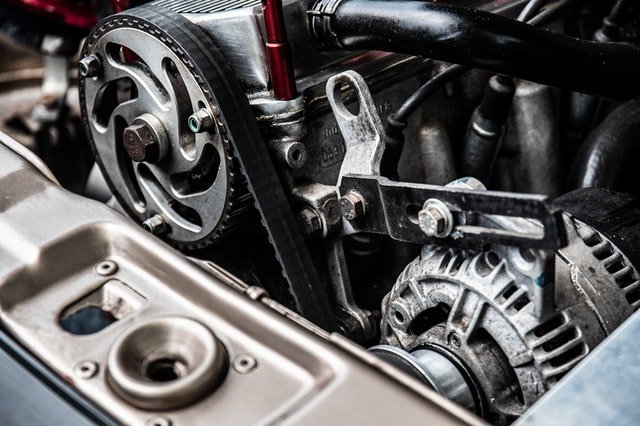

Why Duplex 2205 Performs Well in Seawater

Duplex 2205 is readily recognized by the equal structure which provides strength and corrosion resistance. This is why it is ideal in salty and wet marine air with normal steel likely to rust quickly. Duplex 2205 has a greater strength and stress corrosion cracking resistance when compared to many SS 316 fasteners. Offshore designers prefer it as it enables them to have light designs without compromising on safety. The material is also good in splash areas and damp rooms where the water continues to dry and refreeze on the metal surfaces.

Use in Structural Frames and Deck Equipment

On offshore rigs and platforms, walkways, railings, cranes and support frame are joined together with bolts. These components are constantly vibrated and exposed to weather and hence the fixing mechanism has to remain solid over years. In these areas Duplex 2205 bolts are usually selected to minimize maintenance and replacement efforts. In extremely inhospitable areas, engineers can go so far as to replace with Super Duplex Fasteners to provide additional corrosion defense. Such materials assist the operators in ensuring they do not breakdown at regular intervals and ensure the crews are safe when operating above open water.

Role in Piping Systems and Process Units

Offshore pipelines are used to transport oil, gas, sea water and chemicals across systems. Flanges and valves will require bolts that will support pressure and corrosion simultaneously. In such joints, Duplex 2205 can be successfully utilized and in many cases, it replaces older carbon steel grades. Also, alloys such as Inconel 625 Bolts or Hastelloy C276 Fasteners can be found in special high-heat or chemical areas besides duplex materials. The choice of every grade is determined by the fluid type and the exposure level by engineers to ensure the entire system will last longer without leakages.

Conclusion

The operations that are done offshore rely on fasteners, which will be able to resist corrosion at the same time and be able to resist high pressure. Duplex 2205 has been found to be useful in construction, piping system, as well as deck apparatus in the marine undertakings. Vision Alloys is able to meet these requirements by providing high quality fasteners and close quality inspection of offshore service. Vision Alloys closely consults with customers to propose the most suitable material to use in every zone and level of duty. By selecting powerful alloys and reputable vendors, the offshore platforms remain safer, maintenance reduces and the long-term performance can be enhanced even in the most adverse ocean environment.